Circular concrete. Let’s everox that.

Sustainable construction materials, upcycled from end-of-life concrete

The construction materials challenge

Every year, the world produces ca. 4 billion tons of cement, accounting for 8 % of global CO₂ emissions. Simultaneously, 3 billion tons of concrete waste are downcycled or discarded.

Upcycling to decarbonize concrete

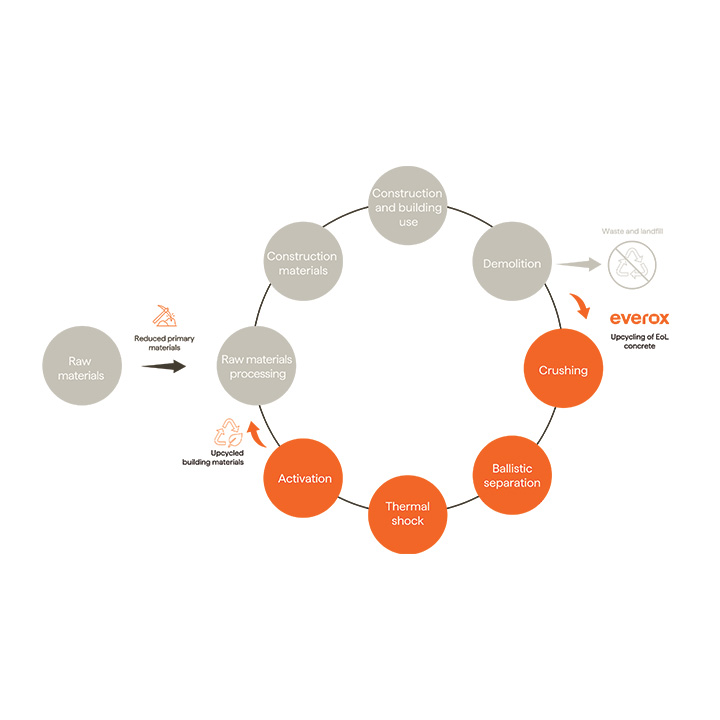

everox transforms waste concrete into high-quality drop-in substitutes for cement, aggregates and sand. Unlocking the value of concrete waste to decarbonize new concrete while enabling a global transition towards a local, circular, and sustainable production of building materials.

everox sustainable vision and mission

We envision to reduce global CO₂ emissions by 2% by phasing out the use of virgin materials in concrete via the patented everox waste concrete upcycling process.

Concrete waste upcycling with the patented everox process

The concrete industry is at a breaking point. For decades, its linear “take-make-waste” model – extracting raw materials, manufacturing products, and discarding them – has remained unchanged, along with its environmental impacts.

“We believe it’s time for a fundamental shift in the concrete industry, from extractive to fully circular.”

Thomas Petithuguenin, everox CEO

Our process transforms end‑of‑life concrete into four high‑value drop-in substitutes for cement:

The game changer: Activated Cement Paste as a sustainable SCM

In traditional recycling processes, cement paste is treated as waste and is therefore lost. But this materials holds immense value. By recovering and reactivating the cement paste trapped in concrete, everox can replace up to 30 % of new cement, drastically reducing the carbon footprint of new concrete mixes.

How to reduce CO2 footprints with Activated Cement Paste as a novel SCM

How can concrete fines become a profit driver while reducing the carbon footprint? everox Activated Cement Paste can lower cement demand, cut CO2 emissions, and enable resilient local supply chains – all at the same time.

Learn more

Building a market-competitive, circular concrete economy with local value chains

There is an urgent need for alternative building materials for several key reasons. The three most important are:

- The primary materials: sand, gravel, and ingredients of cement, are becoming scarce

- The construction materials industry is under pressure to reduce its CO₂ emissions

- Over reliance on global supply chains creates uncomfortable vulnerability

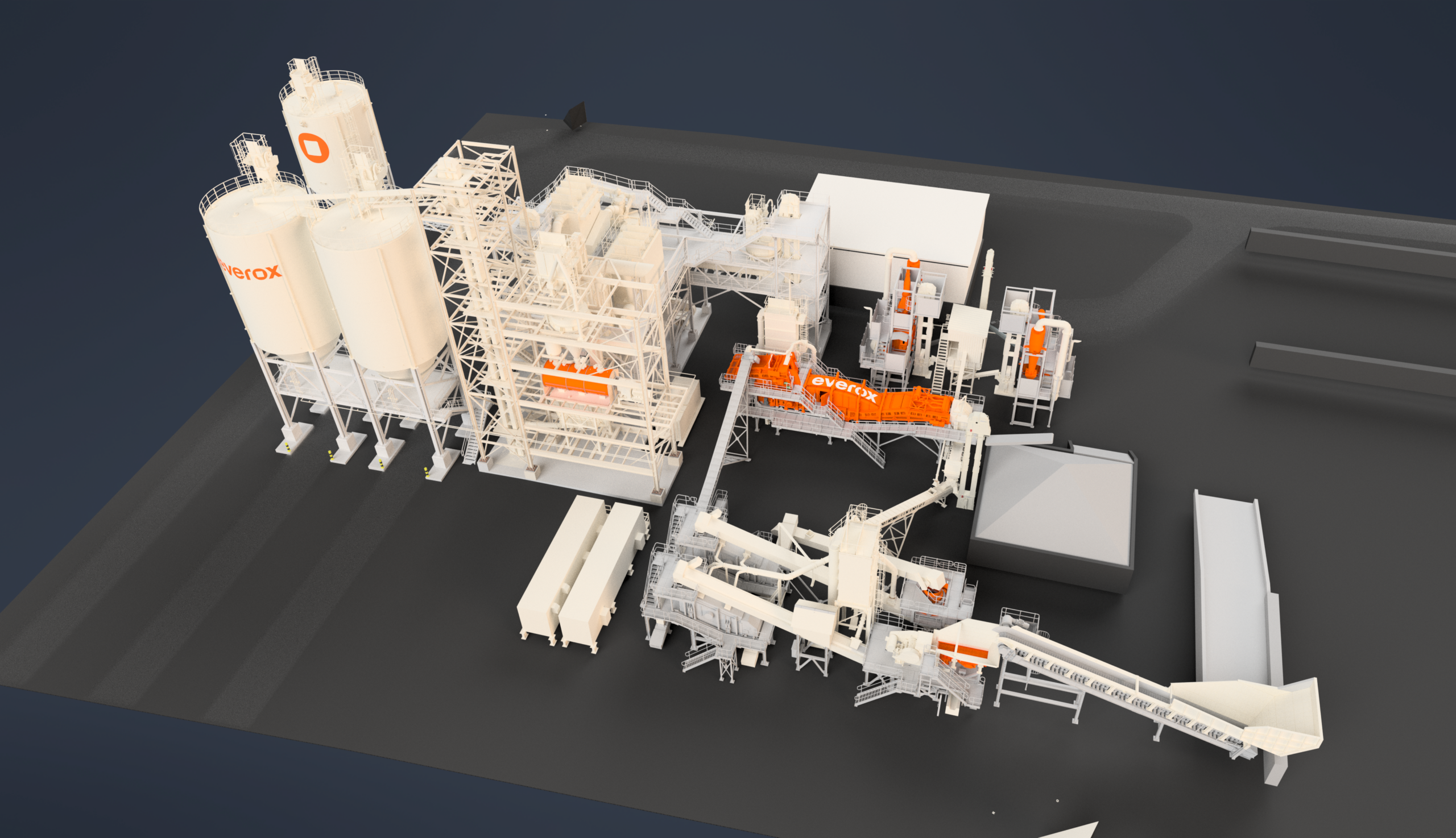

everox’s unique process is specifically designed to upcycle the end-of-life concrete in a way that the materials serve as replacements for primary cement, gravel, sand, and fine inert filler, in newly produced concrete.

Making the plant a perfect addition to all construction materials producers, demolition companies and recycling hubs.

Due to its low energy consumption, space requirements, and lower logistic efforts, upcycled materials can be produced to market competitive prices.

The everox Garden: Research-driven, reliable equipment, and new material standards

At everox, fact over fiction guides everything we do.

We validate our results conscientiously by in-house testing and independent third-party verification, because real progress demands real proof. That commitment led us to create the everox Garden: a unique space where innovation grows from the ground up.

Material certification in progress

everox is pioneering the establishment of new material standards for the industry. Although the certification pathway for novel Supplementary Cementitious Materials (SCMs) is complex, our four innovative materials are already advancing through EU-standard recognition and national approval processes in the Netherlands. In parallel, everox is pursuing a European Technical Assessment (ETA), which will enable rapid CE certification across all EU member states, ensuring reliable, compliant, and future-proof performance for our partners.

Reinventing concrete: Unlocking a global circular materials market

The concrete industry is on the verge of transformation, and everox is positioned to lead that shift. As global pressure mounts to reduce emissions, resource use, and waste, the sector needs more than incremental improvements. It needs disruption. At everox, we are technology and thought leaders in waste concrete upcycling and the production of low-carbon, high-performance concrete materials. Our approach unlocks value where the industry has traditionally seen waste. Transforming end-of-life concrete into a scalable source of high performing, circular raw materials.

We are reinventing concrete.

How to establish novel, low carbon building materials in the market

Download

Our Values

Fact over fiction

We address our goals and responsibilities head on

Approachable

We’re removing barriers and excuses to transition

Holistic

Business profitability x 100% circularity

Impact

We’re here to drive positive, lasting change

Let’s work together

If you are interested in building sustainably, we should talk. We are on the lookout for partners to build plants and facilities to upcycle concrete. Our goal? To enhance your business through circular construction solutions. Share your vision, and we will craft a tailored business case to make it happen together.

Start calculating